Carbonal Co., Ltd is a professional carbon fiber bicycle parts manufacturer in China, specialize in the design, R&D,manufacturing and marketing of carbon fiber bicycle products, main products are carbon mountain bike & carbon road bike parts, including carbon rim, carbon frame and other carbon bicycle components.

Product variety is complete in specifications and excellent for quality. In addtional to 5000

㎡ warehouse and advanced production equipments, Carbonal also provide customized service to customers. At present Carbonal have 3 production lines respectively for rims, frames and other accessories.

http://www.carbonalbike.com/

Let's go to Carbonal bike factory production line to have a look.

1.Material cutting and preparation, the first step of the production line, here we can see many carbon fiber cutting and stamping machines. Carbon fiber cutting is the key to achieving high quality laminate. Carbonal workers handle all original Toray T700 and T800 carbon fiber carefully, precisely control the laminate angle and thickness of each carbon fiber, and guarantees the consistency of products. It's an important part for building ligher and stabler product structure with less carbon fiber. Also have basalt material used on the rim braking surface for increased stopping performance and durability.

2.Pre-Preg and Layup, the thin, pliable sheets of carbon fiber impregnated with resin, so you can make any shapes as you want, high TG resin be used to make carbon bike rim is good enough at high temperature heating on wheels during braking.

Then the carbon prepreg is assembled around a pneumatic core that provides an out ward force on the rim during carbon curing, for other parts (same: small strips of carbon around a solid core inside a mold.

3.Molding. Before we get into the molding area, many steel molds on the side corner, a lots money invest here.

Many molding machines in the molding area, it is a little bit hot at this area even though has air conditioning system here,the carbon cured at high temperature in the molding machines (hot press molding,PC hydraulic molding machines with pressure temperature and time control).

4.Machinery Work. Work about bonding joints,drilling holes and checking the appearance of raw finish frame/rim.

Frame bonding

Frame maching

Listed rim sections with common quality issues

Raw finish rim appearance checking (QC station)

Rim spoke hole drilling

Rim spoke hole drilling

5.Sanding and Painting.

Sanding area

Painting area

The storage boxes on the left of above photo is for painting workers, they need to change the shoes and clean themself when get into painting room, the purpose is to ensure the painting room absolutely clean.

Decal and Painting.

6.Quality control and packing.

Quality control one by one before packing

Scan the barcode on every rim into the computer system, each rim details include date of order/production, rim finish, spoke holes, quality etc. can be tracked anytime if you input the barcode.

7. Shipment:

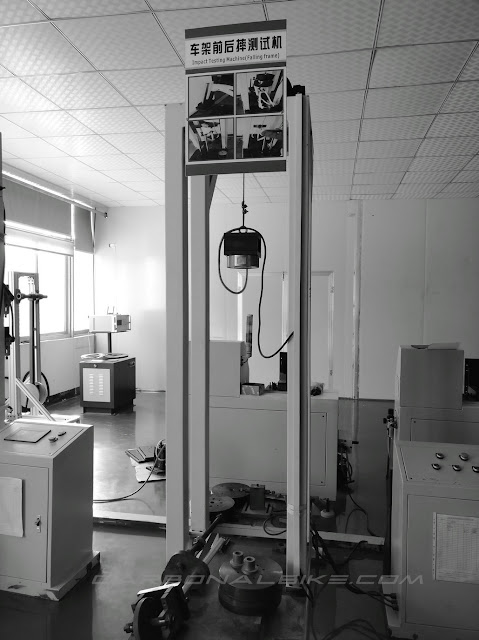

8.Testing room.

Brake testing machine

UCI Impact testing machine

Disk-brake fatigue testing machine

S/T fatigue testing machine

H/T Fatigue testing machine

Fork fatigue testing machine

Fatigue testing machine

Impact testing machine (falling frame)

Universal testing machine

Different tires for testing different rims